MT.connect

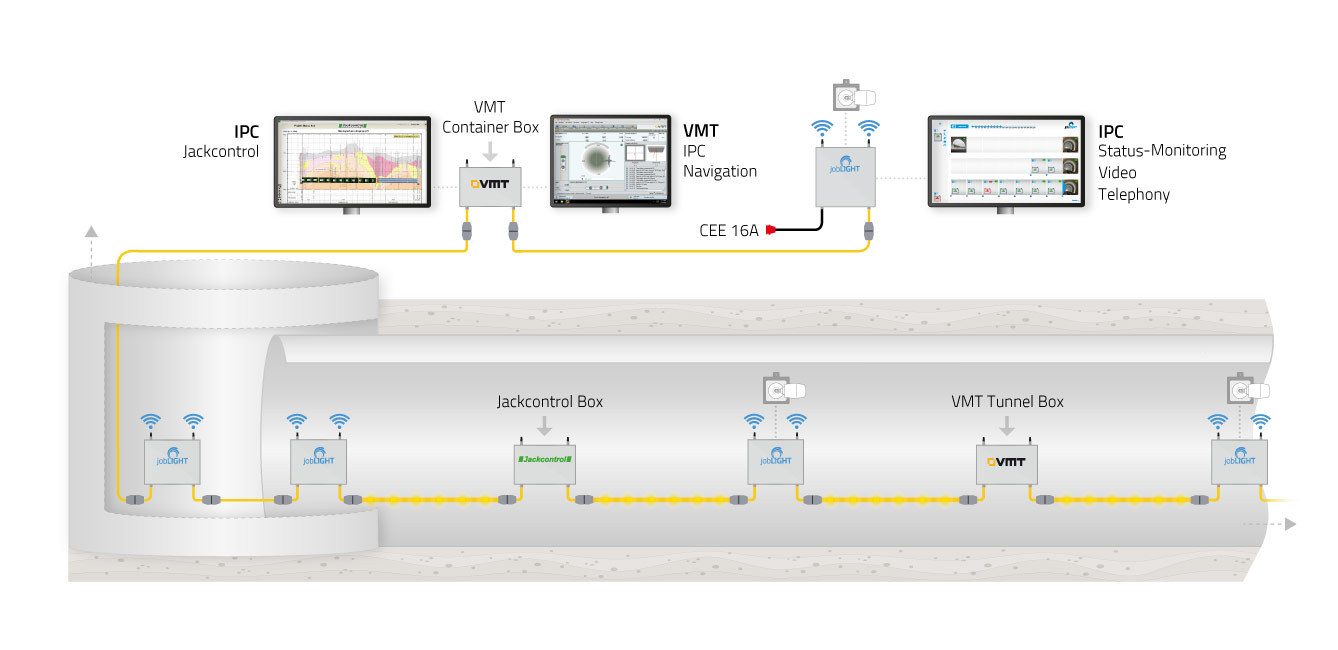

MT.connect is a network-based hardware platform based on state-of-the-art technology. The use of open industry standards offers future-proofing and simplifies bidirectional communication with third-party systems and external sources. By consistently reducing hardware components to an absolute minimum, we simplify handling and spare parts management. Through the close cooperation with our strong partners Jackcontrol and Atcetera, we are breaking completely new ground and using synergies by combining different trades and functions, while bundling them under one platform.

The hotline to colleagues

The integrated WLAN not only provides communication between the surface and the tunnel, but also allows the exchange of photos and short videos. This saves considerable time in the elimination of disturbances.

Fully compatible

The open industry standard as the basis of the system allows not only the integration of third-party systems, but also the integration of our system into other applications. This reduces the installation effort, reduces coupling points and saves space.

Less is more

The reduced number of components saves storage costs and simplifies handling. New functions also support troubleshooting, thereby ensuring high system availability.

Increased operational safety

Optimally tuned

Both the new MT.connect HW platform – as part of VMT’s internal overall VMT.connect solution– and the TUnIS software platform are in-house developments and thus perfectly coordinated. Interface problems can therefore be ruled out. Special monitoring tools create additional transparency and always keep an eye on the system status.

Quick relief

If, however, a component should fail, the universal spare parts box will provide quick relief. Thanks to optimised spare parts management, you are prepared for anything – with little effort. Unplanned downtimes are reduced to an absolute minimum.

An investment that pays off

No limits

The chosen technology is not subject to any limitations in terms of drive lengths. Should it ever become tight and the pipe jacking have to be converted to segmental tunnelling, the MT.connect platform is prepared and guarantees smooth transition between the systems.

Synergies that pay off

With Jackcontrol and Atcetera, further established microtunnelling partners rely on MT.connect technology. The resulting synergies reduce investment and maintenance costs.

Extended benefits

Condition monitoring provides a detailed overview of the status of all connected components and indicates critical conditions at an early stage. Timely action extends the life of the system.

Equipped for the future

On the cutting edge

A wide variety of modern devices can be integrated into the selected network infrastructure with high data rates. Whether smartphone, network camera or even AR (augmented reality) tools – they all use the WLAN in the tunnel and enable fast, solution-oriented support directly on site.

Always stay on top of things

Cross-system data management creates transparency: The open industry standard OPC UA as the basis of the MT.connect platform simplifies communication with applications from other manufacturers.

Look to the future

Modern technology as the basis for communication meets all today’s requirements and also creates the pre-conditions for further development of the system in order to meet future challenges.

Stress-free and everything under control

Stable in all situations

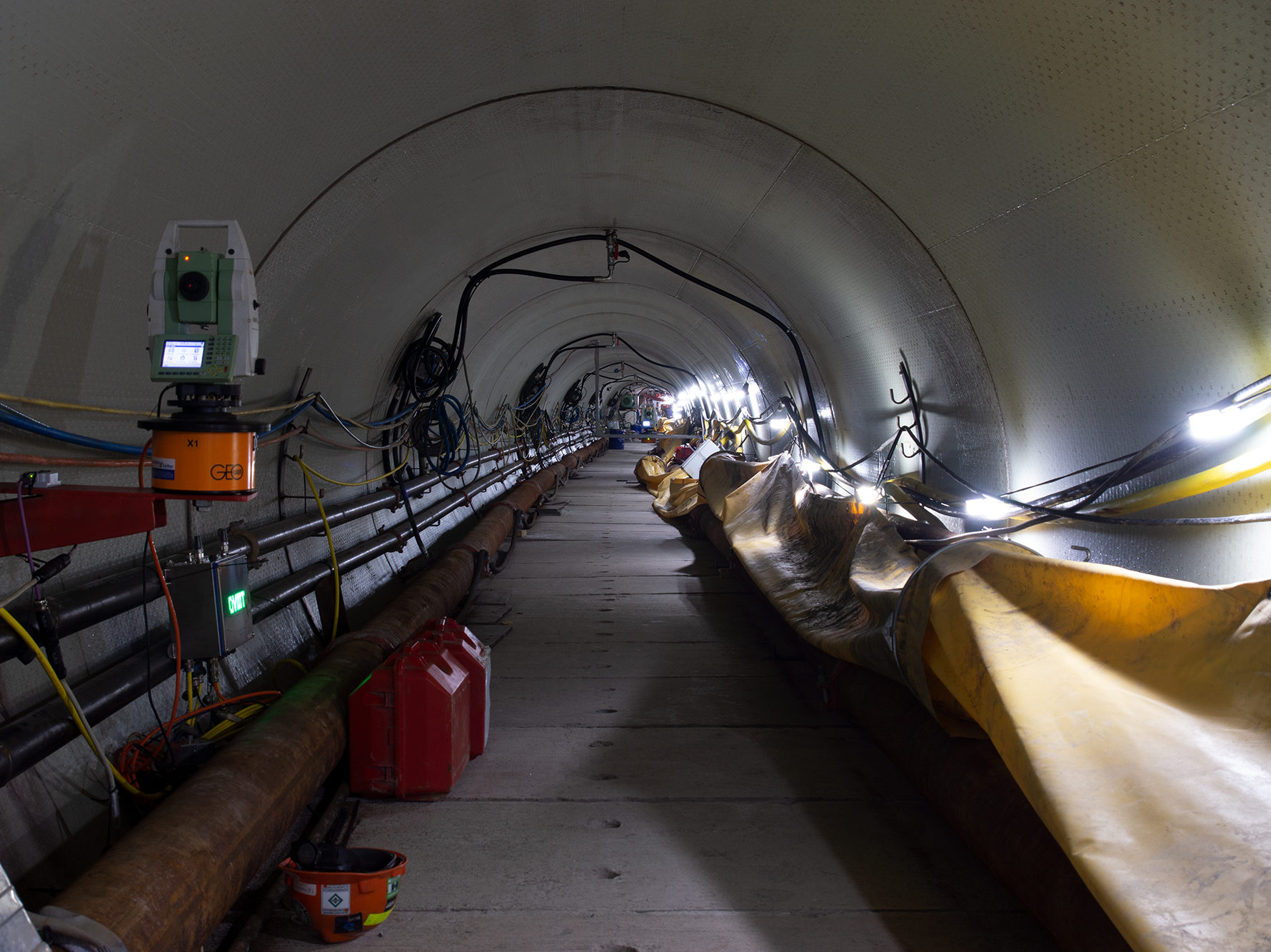

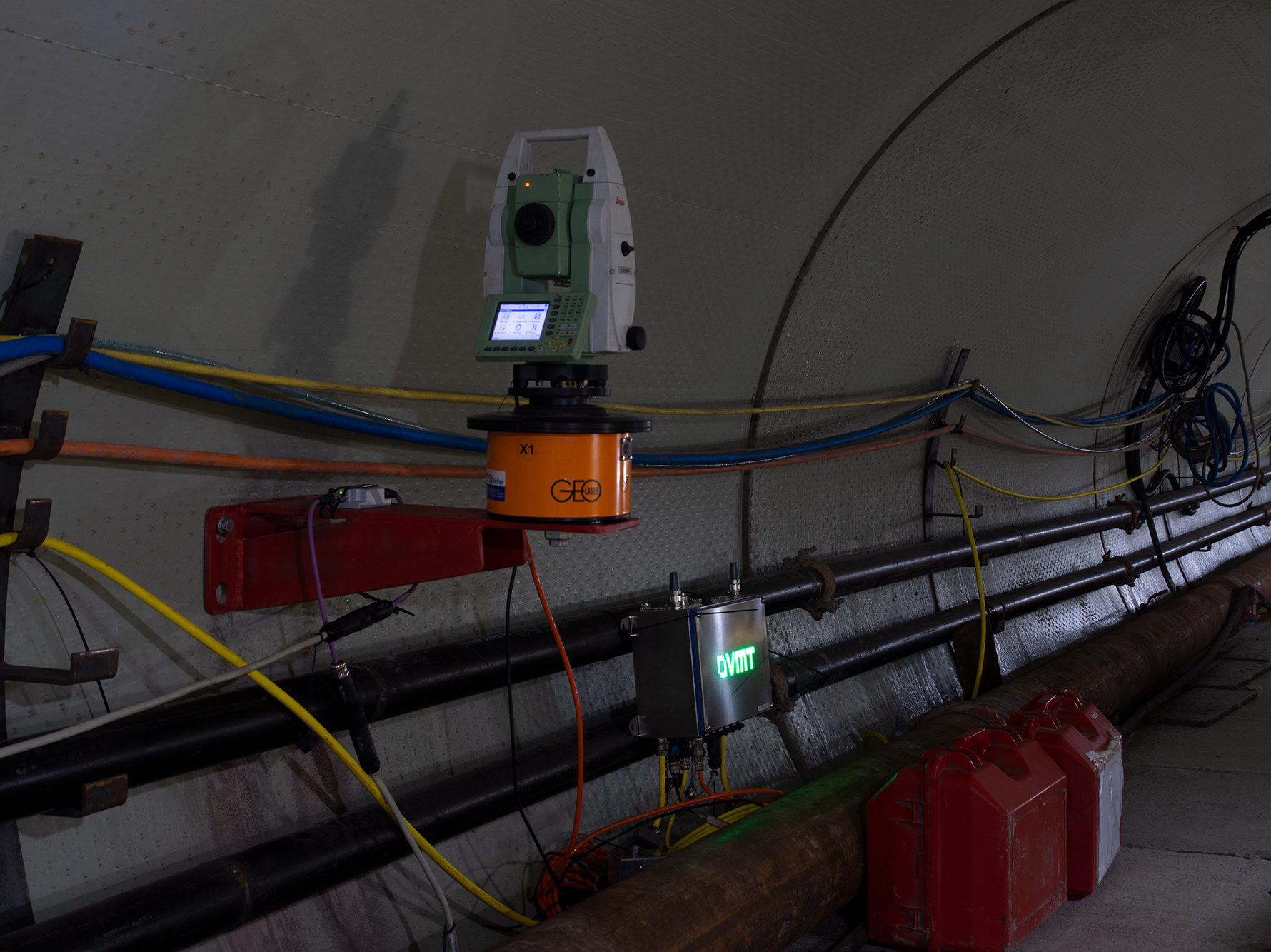

The hardware components are also used in conventional tunnelling, where they have proven their robustness under extreme conditions. Coupled with a revised, optimised voltage concept with central power supply, the system can be relied upon completely.

Keep it simple

One data-line for many uses – whether communication, navigation, joint monitoring or camera images, everything is transported via one data-line. But not only data can be transmitted: A special version of the data cable has integrated LED light strips that simultaneously still realise the tunnel lighting. This simplifies handling tremendously and also saves time and costs.

The MT.connect Hardware platform is the basis of the VMT navigation systems and has already a punctual, unmanaged WLAN included. In conjunction with the fully compatible hardware and software of the Joblight system this WLAN can be easily upgraded to a managed one with seamless coverage inside the tunnel.

Innovative lighting concept

A special feature is the new, innovative data line in which LED light strips can be integrated. In this way, several needs can be fulfilled with only one cable:

• Transmission of data for navigation, communication and joint monitoring (→ Jackcontrol)

• Tunnel lighting including battery buffering (→ up to 60 min full light intensity in case of power interruptions)